- Skills you need to modify your motorcycle (article) [BONUS download included!]

- Planning a custom motorcycle build (article) [BONUS download included!]

- Book list for motorcycle customizers (article) [BONUS download included!]

- Motorcycle Inspection Checklist (article) [BONUS download included!]

- Basic properties of metals (article)

- Threaded Fasteners (bolts & nuts) (article)

- Introduction to limits & fits (article/video) [BONUS download included!]

- Introduction to torque (article/video) [BONUS download included!]

- Introduction to bearings (article/video)

Coming soon:

- How to pack bearings

- How to identify bolts

- Engine oil

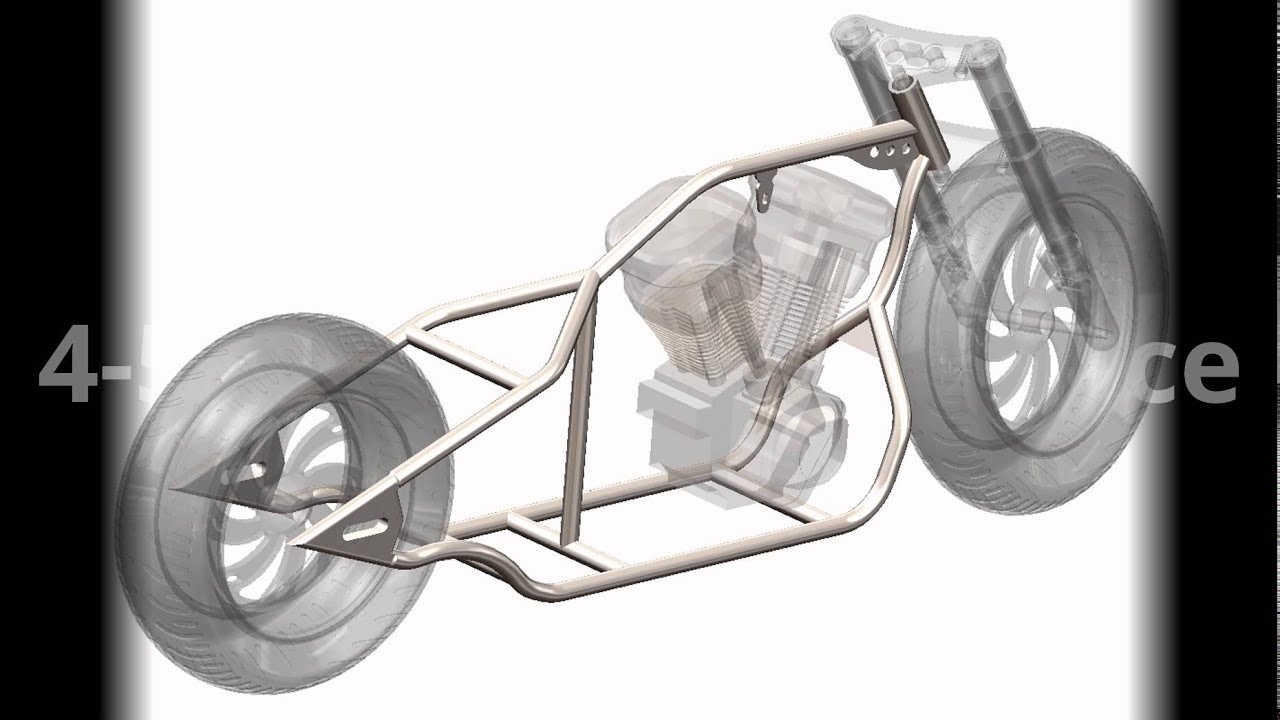

Frames & Frame Kits 14.06 Santee® Frame Kits 14 Prices appearing in this catalog are Suggested Retail Price and are subject to change. 650067 Santee® 250 Chopper ‘Tall Boy’ Frames Custom choppers start here! Santee frames have been the foundation for thousands of custom bikes for over the past thirty years, and now, Santee’s new dual. These frames are configured for forward controls and have a three-point mount on the left-side that will accept a forward shifter bracket and conventional 4-speed kickstand mounting bracket. Stock-style frame for Touring drivelines ONLY $2,133.95. Axle kit for 153FXRW and 153FXRCW swingarms $158.95. As you will see in these free homebuilt chopper plans, I do not offer 'cut here, weld here' type plans at all. In fact, the entire focus of this compilation is to show you how to become a chopper artist by looking at how I built my bikes in order to form your own ideas and designs. You can build a custom chopper using basic tools and skills. There are currently 8 unique mini chopper designs and many more on the way! Each frame is broken down step by step. Also included are build jig details for each frame. This is a must have when building a straight and accurate frame. The easy to build 2″X4″ wonder jig cost less than $6.0 to build. The most valuable part of the plans is the.

- A simple timber motorcycle build platform (free plans/article) [BONUS download included!]

- Motorcycle build platform (advanced) (article)

- Air compressor overview for motorcycle shops (video)

- Hercus 9″ lathe restoration (article/video series)

- How to build a killer (lathe) bench (article/video series)

- Radial draw tube bender build (article/video series)

- Building a 12V & 24V bench-top power supply (article, schematics, drawings)

- How to build an air-tool rack (video)

- Reverse engineering a DIY anvil build (video)

Coming soon:

- Shop tour!

- Hand tools basics (article/video series)

- Tools: Price vs Quality (article)

- Wrenches – how to choose the right ones (article) [BONUS download included!]

- Screwdrivers and screw types (article)

- Pliers for motorcycle maintenance (article)

- Recommended tool list: mechanical (article)

- How to make: Motorcycle Chain Master Link Pliers (article/video)

- Socket Storage Project (article)

- Top Tools: Angle Grinders (article) [BONUS download included!]

- Top Tools: Dremel Multi Tool (article) [BONUS download included]

- Workshop safety and hazard awareness (article/video) [BONUS download included]

Coming soon:

- Hammers and mallets

- Measuring tools

Brakes

- Dyna rear brake caliper repair…and fail (article/video)

Engines

- The ABCs of carburetion (offsite, free PDF download)

- The ABCs of fuel injection (offsite, free PDF download)

- Custom exhaust construction (article/video)

Coming soon:

- How to identify worn chain and sprockets

- Electrical basics (article/video series)

- The contact breaker (points) ignition system (article)

Coming soon:

- Electrical 101 – Voltage and batteries

- Electrical 102 – Series circuits

- Electrical 103 – Parallel circuits

- Electrical 104 – Resistance

- Electrical 105 – Conductors (wires)

- Electrical 106 – Soldering

- Electrical 107 – Crimp connectors

- How to fit a frame hoop (article/video)

- How to modify steering stops to suit a custom front end (article) [BONUS download included!]

- How to shorten a steering stem (article/video)

- How to make fender struts (or a sissy bar) (article/video)

- How to remove a steering stem bearing (article/video)

Coming soon:

- Chassis jig

- How to clean out fork seals

- How to shorten a steering stem

- How to smooth a top triple clamp with files

- How to restore a spoked hub

- How to re-radius a fender

- How to restore and polish metal surfaces (article/video)

- How to paint your motorcycle parts (article/video) [BONUS download included!]

Coming soon:

- How to paint an engine (cheap!)

- How to remove paint

Chopper Frame Blueprints Pdf Free

- Essential metal fabrication tools (article)

- Introduction to welding (article) [BONUS download included!]

- First TIG welding lesson (video) [BONUS download included!]

- Getting started with metalshaping – beater bags & mallets (video)

- Getting started with metalshaping – tucking forks (video)

- Getting started with metalshaping – making a shrinking bowl (video)

- How to metalshape a custom fender (video) [BONUS download included!]

- How to QUICKLY layout bike lines with a wireframe buck (video)

- Tools & techniques for making holes (Facebook Live video/article) [BONUS download included!]

- Ideal Speeds For Drilling Metal (FREE calculator – Google Drive & Excel)

- What welding equipment should I buy? (article) [BONUS download included!]

- How to anneal aluminium (for metalshaping) (video)

- How to fabricate a motorcycle luggage rack (video)

- How to weld repair cast aluminium parts (video)

Coming soon:

- How to weld repair cast iron

- Getting started with metalshaping – hammer and dollies

- Getting started with metalshaping – slapping hammer

- Custom machining some luggage tie-down bungs (article/video)

Coming soon:

- Tool repair with TIG welding

- Brain dead workshop fun – TIG torch holder

Chop That Frame Up!

Chopper Frame Blueprints Pdf Online

How to Build a Mini Chopper Frame and Schematics

The frame design is one of the most rewarding parts of building a mini chopper, so if you are able, we strongly suggest building your frame rather than buying one. However, you must be sure of your welding ability. Either you, or someone you love will be supported by it, and traveling fast — you do not want this thing to fall apart.

Thinking About Frame Design

The first thing to do when considering the frame is what you want it to look like. If you

haven't already discovered it, there are many different styles of frame design, and subtle nuances to each. Surf our photos and others, and print a few out. This will help you sketch your own ideas better.

Using a Bender For the Frame Design

There are two main ways you can make your frame — with or without a bender. A frame that is square rather than rounded simply will not look as good. Our frame was made from 3/4' pipe, bent with a Harbor Freight hydraulic pipe bender.

[Learn about bending and selecting material].

How We Built the Frame

First, we cut and bent two sections of pipe to the same bend, roughly 100 to 110*. It's not too time consuming to bend them equally in the pipe bender, though it's not an exact science. We've heard that if you count the pumps you can make the same bend twice, so you may try that method.

Then we made two 90* pieces of material for the rear wheel assembly. Since the pipe bender won't make a 180* bend, you must make two pieces and then weld them together in the 'U' shape. This 'U' should be longer than necessary so you can cut the material to length when you mock it up.

The backbone tube was then welded to the 'U' assembly. This will need to be very square. To accomplish this we laid the assembly on the concrete and traced the 'U' shape. Using a carpenter's square we drew two parralell lines toward the backbone. Then we drew a 90* line through the two lines. From this line we were able to draw squared lines that outlined where the backbone was to be attached.

You must fishmouth the joint between the 'U' and backbone. This can be done with a grinder.

Assembling the Upper and Lower Parts of the Frame

Take the two pieces making the lower assembly, and lay on the concrete. Take your upper assembly and mock up how you'll like the stretch of the frame to look. Since you cut all the materials longer than needed, you'll have some options.

Fabricate the Engine Mount

You can read more about these options in the parts section.

Engine mount was custom sized for the frame from a purchased engine mounting plate and 1/4' flat stock welded to form the correct size. When welding long welds like these, ensure that you tack first and use lots of short welds so you don't warp the plate or frame.

You can make your own mounting plate, but it's often cheaper to buy them, and you won't need cut the slots for the mounts.

Position The Engine

When designing your frame, consider where your engine will fit. You'll want the engine to be close to the rear wheel to minimize chain length and position the clutch farther from your legs.

Tack the plate in to your frame and place your engine on it, noting the adjustment travel, exhaust and carburetor clearances